The system is flexible so it can adapt to your operations.

Mrp and shop floor management tools.

In addition it processes real time data so you get an analysis straight in your dashboard.

A prime requirement for job and machine shops is manufacturing resource planning mrp the system that schedules the manufacturing of each customer s order.

The scheduling needs to account for a level of variation that is typically beyond the scope of the planning systems mrp master scheduling and the like.

Today s shop floor is a complex continually varying environment.

Screenshot of e2 shop system scheduling whiteboard.

Schedulers need full visibility into all shop operations to control the details of each job and ensure the required machines are available.

An mrp helps manufacturers with their bill of materials business planning capacity requirements planning computer aided design configuration management contract management cost control costing methods engineering change control finite capacity scheduling inventory tracking production data and schedule project management purchasing management sales analysis shop floor control and tool management.

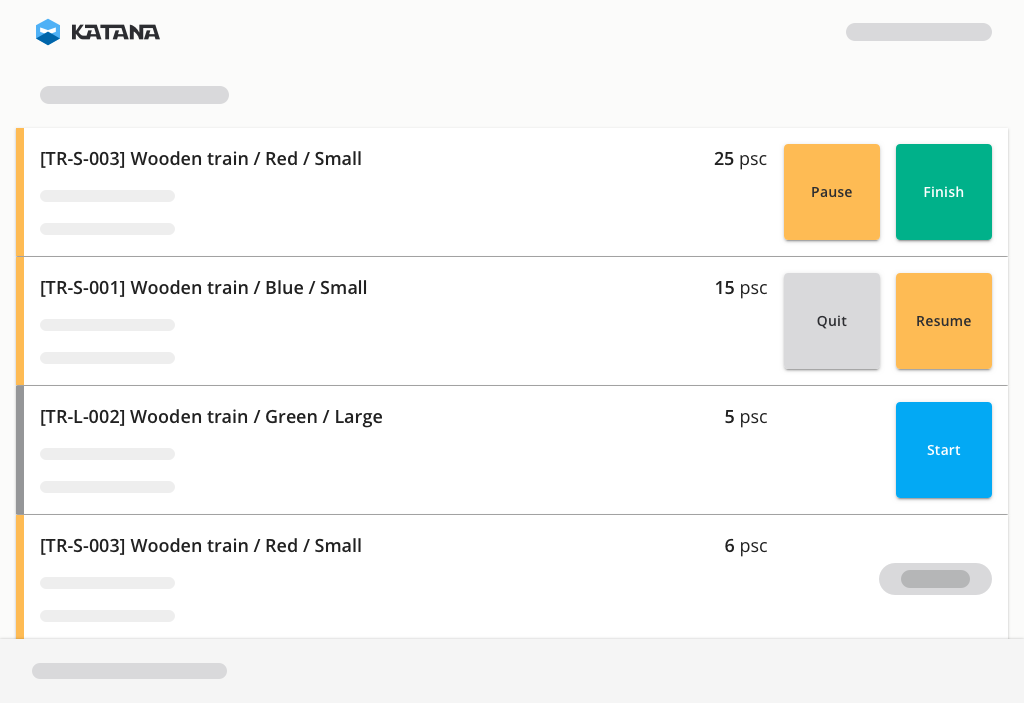

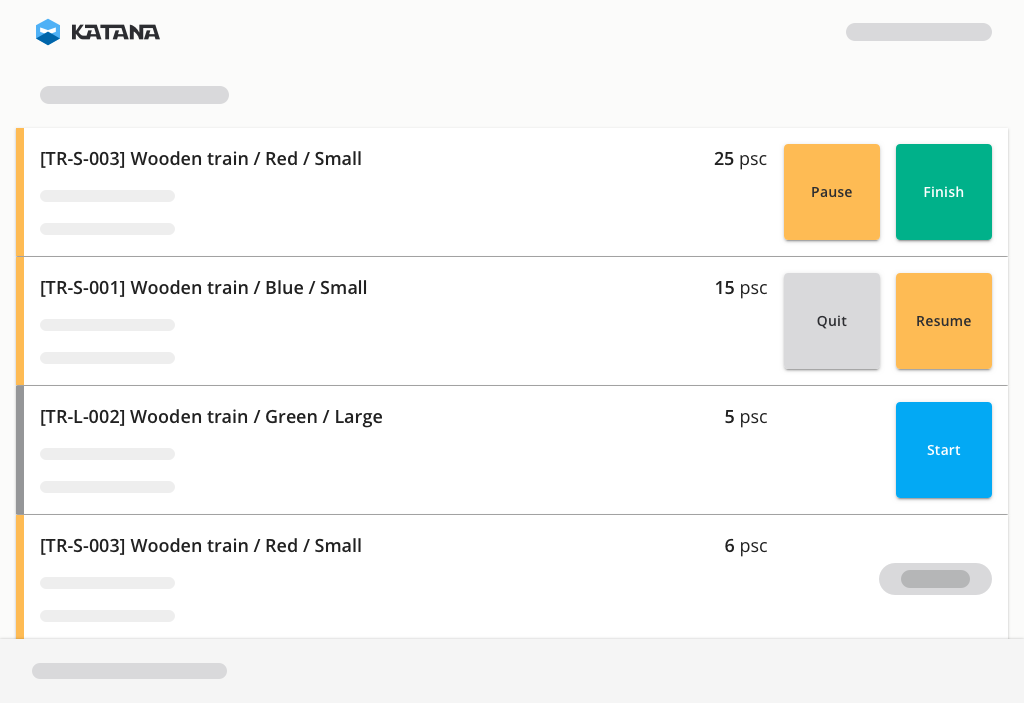

Shop floor planning and control is the process of using methods and tools to track schedule and report the status of work in progress wip manufacturing from your floor level giving you a clear channel of communication between your operators and managers on the production line.

From the shop floor to the top floor netsuite s manufacturing cloud erp keeps the modern manufacturer in sync built for manufacturers there s more to your business than manufacturing and netsuite offers a complete erp software solution that benefits your entire organization.

Inventory and order entry are important and must be integrated with the mrp system particularly with the pipeline management system.

Using a variety of jobboss scheduling functions you can respond to customer requests quickly with up to the minute data of your shop floor capacity.

Mes systems can provide data about shop floor conditions to mrp software that can be used to coordinate the timing of material procurement activities to support just in time initiatives that lower inventory carrying costs.

Shop floor control delivers the ultimate solution to running a manufacturing plant profitably by allowing you to accurately predict production costs based on estimated material labor and overhead and allowing you to analyze actual production costs.

With prodsmart you can transition to digital shop floor monitoring with ease.

Mes automation considers and controls the highly critical details of a typical plant shop floor.