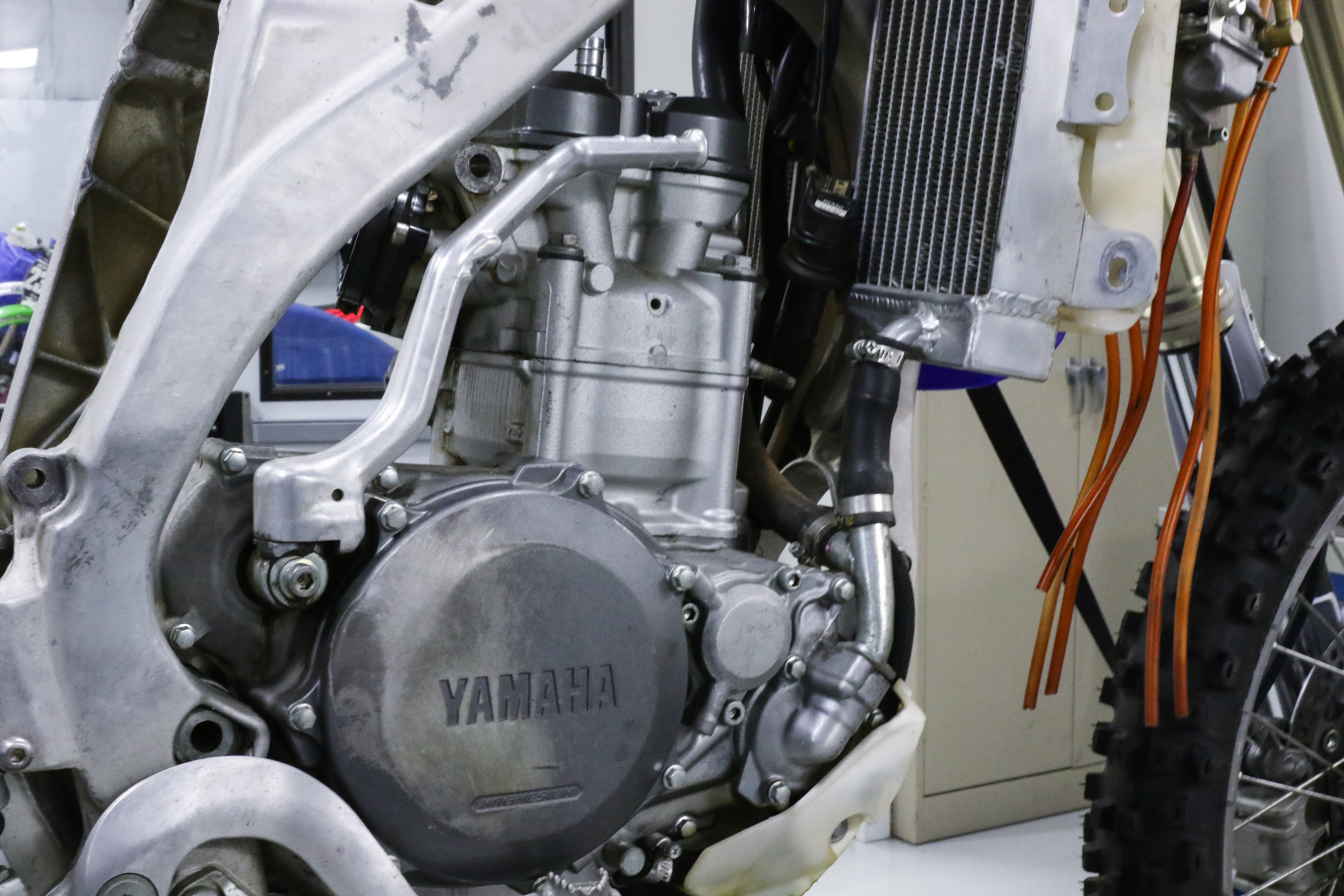

They keep everything running smoothly in the connection between the axle and the wheel and they also reduce the amount of heat generated when they spin.

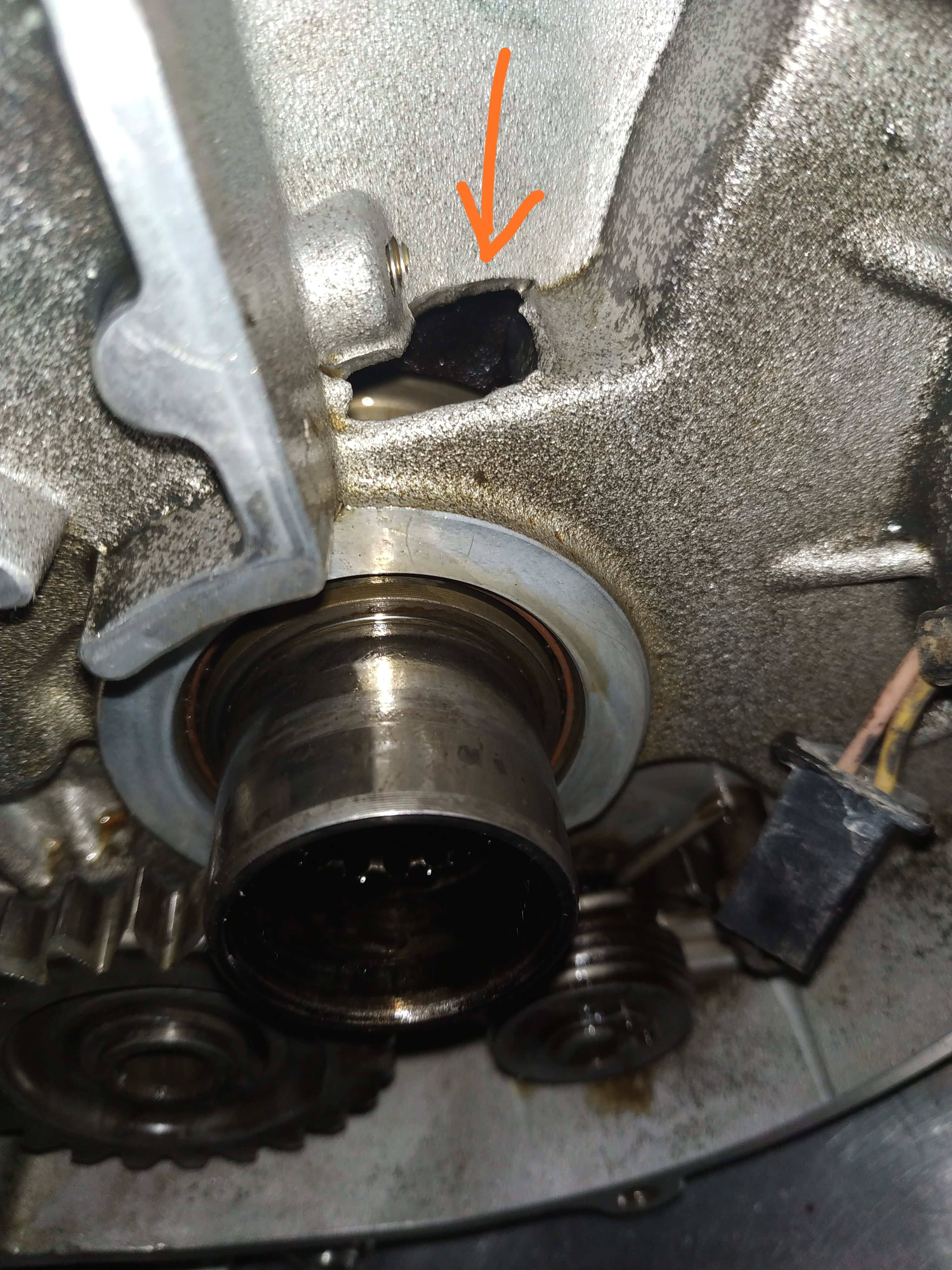

Motorcycle ball bearings spinning in crankcases.

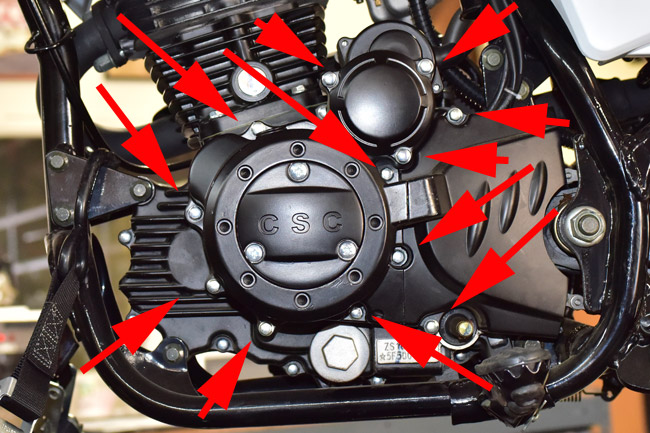

Best ways to remove all crankcase bearings.

These sealed wheel bearings can last as long as you own the bike if you treat them right.

So i have cases apart and all bearings need replacing i have a hot plate a paint stripping hot air gun and a gas bbq are any of these of use or do i have to use an oven open to all help on this many.

The drill only needed 1 42 amps to spin the hybrid ceramic bearing.

The same bearing is rated for a 30 000 pound load.

That is 2 75 times longer than the steel ball bearings.

Pic 6 i couldn t believe it.

However overloading the motorcycle riding in deep water that goes over the hubs directing a pressure.

The wear on a plain bearing engine occurs when the engine is first started.

Next was the amperage that the drill needed to spin the wheel.

All balls racing wheel bearings feature high speed bearings that are manufactured to abec 3 precision levels triple lip rubber seals that keep the grease in and the water and dirt out all while utilizing a chevron sri 2 grease that contains rust and oxidation inhibitors.

So the inner race needs a press and the housing does not in your case.

At 60 mph a 21 inch wheel including the tire is only spinning at 960 rpm.

There are several ways they are used.

Plain bearings with no bushing are usually used for the camshaft in the cylinder head.

Normally bearings allow the crank glide on a hydrodynamic film of oil between the bearing surface and journal.

It is impossible to overheat anything like the crankcases.

Spun bearings are often blamed on a loss of oil pressure but there can be numerous contributing factors that eventually cause the bearing to seize and spin.

We don t have room for our math which describes the free falling.

An often overlooked but key component of any bike wheel is a motorcycle wheel bearing.

The hybrid ceramic bearings had a long free spin time.

On ball bearings your press fit is the part that rotates and the other part is a snug but sliding fit.

Remember the drill alone without spinning the tire took 1 38 amps.